On the DanMAX beamline, a concentrated X-ray will be sent out to two measuring stations, enabling researchers to see inside a wide range of materials. One of these measuring stations is an X-ray microscope.

|

|

Safer drugs

When you are in the business of manufacturing a wide range of drugs—crystalline drugs such as Paracetamol, for example— it is essential that you understand and control the crystallization processes. With the help of DanMAX, X-ray diffraction methods can be used to monitor the crystallization of substances from a solution—and to monitor chemical changes such as water absorption and dessication under changing temperatures and humidity.

DanMAX will enable researchers to study much closer the crucial early stages of crystallization and structural changes over time than is currently possible.

|

Better biological materials

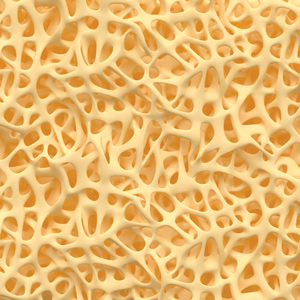

Nature offers a wealth of examples of sophisticated properties—mussels that can glue themselves to both rough and smooth materials under water—or bones made of a complex composite material of nanocrystalline calcium phosphate and proteins that affords lightness and strength.

Due to the lack of analysis tools, the bones’ structure and shelf-life, for example, are far from understood. The same applies to the consequences of using artificially produced biomaterials in the body. With DanMAX, researchers will be able to examine samples in complex environments, 3D, and over time—and thus be able to develop materials with advanced properties. In addition, the beamline is designed for analyses of biological and bio-inspired materials.

|

|

|

|

|

Stronger metals

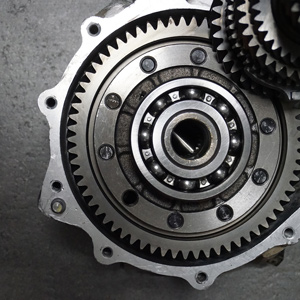

With X-ray microscopy you can map cereals, orientations, phases, and local voltages in polycrystalline materials such as metals, ceramics, and certain building materials.

With DanMAX, you can establish and test materials models and gain a more detailed understanding of how metals are deformed and harden, and how dislocations arise—thus paving the way for new, more durable materials in such sectors as energy and construction.

|

New food products and packaging

DanMAX will enable researchers to analyse food products such as meat, emulsions, dairy products, sweets, and fruit to create new state-of-the-art packaging. The development of new products requires effective and powerful techniques that can map the product components without damaging them.

3D, high-contrast, X-ray imaging is ideal for analysing tissue (e.g. lard) and light materials, making it possible to follow processes and see structural changes in the food as they are taking place—during heating and cooling, for example.

|

|

|